Product Description:

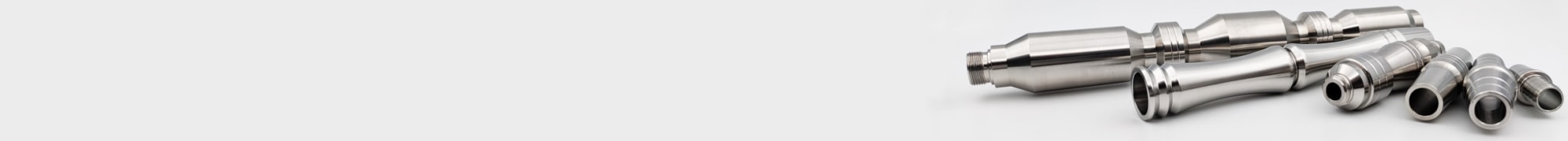

Name: Custom CNC Stainless Steel Pan - Head Screws

Material: 303 Stainless Steel, 304 Stainless Steel, 316 Stainless Steel

Color: Customizable

Surface Treatment: Electropolishing, PVD

Description: Enhance the stability and visual charm of your assemblies with our Custom CNC Stainless Steel Pan - Head Screws, which are precision - engineered to offer both reliable functionality and an attractive appearance. Made from high - grade 303, 304, and 316 stainless steel, these screws with their distinctive pan heads are designed to meet the strict requirements of precision equipment and vehicles, providing durability, customization options, and a refined finish.

The selection of materials ensures that these pan - head screws perform optimally in various applications. 303 stainless steel is renowned for its excellent machinability, making it perfect for manufacturing pan - head screws with complex structures and tight tolerances, ensuring a precise fit in precision assemblies. 304 stainless steel provides superior corrosion resistance and strength, making it suitable for both indoor precision equipment and vehicle components that are exposed to moderate environmental conditions. 316 stainless steel, with its enhanced resistance to corrosion, chemicals, and high temperatures, is the ideal choice for pan - head screws used in harsh environments, such as outdoor vehicle parts or precision equipment in industrial settings.

The pan - head design is a key feature of these screws. The large, flat, and slightly rounded head offers a larger bearing surface, which helps to distribute the clamping force evenly. This not only ensures a more secure hold on the connected components but also reduces the risk of damage to the surface of the parts being fastened, which is particularly important for precision equipment and vehicle components with delicate surfaces.

Surface treatments further improve the functionality and aesthetics of these pan - head screws. Electropolishing creates a smooth, mirror - like finish on the pan head and the entire screw surface. This not only enhances corrosion resistance by eliminating surface impurities but also reduces friction, making installation easier and minimizing wear on the mating parts. PVD (Physical Vapor Deposition) treatment adds a durable, scratch - resistant layer while allowing for a wide range of color customizations. From classic metallic shades like gold, silver, and black to bold colors that match brand identities or design schemes, the PVD finish ensures that the pan - head screws maintain their performance and visual appeal even in high - use or exposed environments.

In addition to the material and finish, these pan - head screws can be fully customized to meet specific needs. Whether you require unique thread patterns, lengths, or drive types, our CNC machining technology can deliver precise results, ensuring compatibility with your precision equipment or vehicle assemblies. The ability to tailor every dimension guarantees a secure and reliable fit, which is crucial for maintaining the integrity of precision systems.

These custom pan - head screws are ideal for a wide range of applications, including medical devices, aerospace instruments, industrial control panels, automotive interiors, engine components, and vehicle trim. They not only securely fasten components with precision but also contribute to the overall aesthetic of the product, making them an excellent choice for brands that value both performance and design.

Our team works closely with clients to understand their application requirements, from material selection to finish and dimensions, ensuring that the final pan - head screws perfectly meet their needs. Whether you need a small batch of specialized pan - head screws for precision equipment or large - scale production for vehicle assemblies, we provide consistent quality and customization.

Upgrade your assemblies with pan - head screws that combine reliability, durability, and visual appeal. Contact us today to create Custom CNC Stainless Steel Pan - Head Screws that meet the unique demands of your precision equipment or vehicles.